Please note our new shipping costs starting April 01, 2024

at https://www.schafwollzentrum.tirol/en/shipping-costs/

Ulrike Wolf

Sale + Shipping

Manuela Regensburger

Organization + Production + Sales

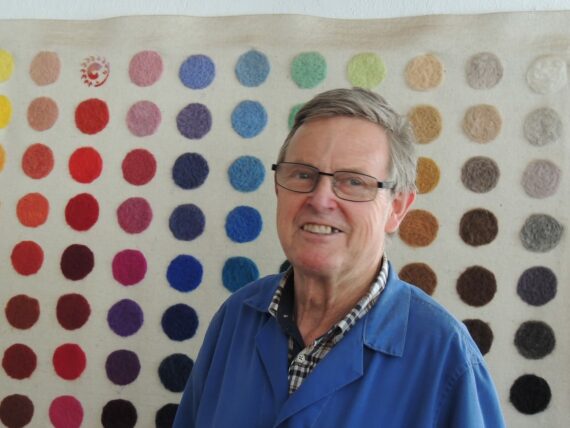

Johannes Regensburger

Senior Boss + Wool God

Joachim Regensburger

Organization + SellingOur products tell a story

We are happy to invite you to experience the stories of our handmade sheep wool products live. For this we offer the opportunity to look behind the scenes of our carpet manufactory and to accompany the regional wool in the production flow. – From the delivery by the sheep owner to the finished carpet. – Like to tell our stories!

Dates: on request // Duration: approx. 1 h // Costs: 5 EUR per person

This guided tour is also advertised by Ötztal Tourism and is free of charge for guests thanks to the cooperation/cost coverage of the tourism association. Wunderfaser Schafwolle | Ötztal Inside Card (oetztal.com)

We are looking forward to your message!

Time for history.

The foundation

The company was founded in 1938 by Otto Regensburger, the grandfather of today’s managing director Joachim Regensburger, for the processing of flax grown in the Ötztal and Tyrol.

Flax cultivation was very important in the Ötztal, both in terms of the amount cultivated and the quality of the flax. The importance of the Ötztaler flax was documented by the fact that the price of flax was quoted around 1800 on the Hamburg commodities and derivatives exchange.

To improve the cultivation of flax, the first Ötztaler Flachsbaugenossenschaft was founded in 1906. When processing the flax into ready-to-use fiber, however, everything remained the same with the old processing methods.

1937/38

The first company building with attached E-Werk was built. In 1938 Otto Regensburger bought in Silesia a modern flax turbine with the associated crushing machine. Thus, the delivered flax could be processed better and with greater fiber yield.

In 1946, a hot water toasted. With this hot water roasting method, the rotting time of the wooden stem could be reduced to a few days. To heat the water, the wood parts used in flax processing were used, even then a closed circuit.

1948

After in the year 1948/49 still 50 tons of flax fibers were delivered to the spinning mill Lambach, in the following year the flax cultivation in Tyrol was on

Dropped to zero kilos. All machines were useless and had to be scrapped. In the valley there was another textile raw material, which should be processed – sheep’s wool. For example, in 1953, Otto Regensburger invested in an old woolen carton and a small spinning machine with which wool processing was started. At the beginning, the wool of the farmers was processed in salary.

1955

At the age of 14, 1955, the training of senior partner Johannes Regensburger began as Weber. Then four years internship in the Tyrolean loden factory Weyrer and visit to the textile school in Dornbirn. In 1962 he joined the family business. As early as 1956, more than 50 years ago, Otto Regensburger began producing sheep wool carpets.

From 1962 to 1966

were woven with four looms for the Tyrolean loden factory Weyrer Wollstoffe in wage labor.1964, Otto Regensburger died suddenly. The carpet production was substantially further developed by Johannes Regensburger, and at that time it was the main production. In the following years, the factory building was extended three times by additions. the last major addition was in 1984.

50 years modern times

In the course of time it had to be made the experience that due to the dying textile processors in Austria and also in Germany it became more and more difficult to process the domestic sheep wool, since there was no possibility to wash the wool in Austria. The entire unwashed raw wool had to be delivered to Belgium in a large laundry.

This development prompted the Regensburger family in 1996 to invest in a modern, innovative wool washing plant. At the same time, the oldest son of Johannes Regensburger, Michael Regensburger, joined the company in 1996.

Other reasons for this decision were:

- In Umhausen there is a completely lime-free, soft water. (hardness 0, minimum use of detergents)

- In Tyrol, about one third of Austrian sheep’s wool is produced.

- Centrally located for the neighboring regions of Bavaria, South Tyrol, Switzerland.

- The washing plant can secure the heel of the wool for the farmers.

- The value added remains for the most part in the country.

Subsequently, the Ötztal Schafwollzentrum Regensburger GmbH. By working with other processors, it is now possible to offer a wide range of special products made from local sheep’s wool with proof of origin.

With much perseverance and dedication, Johannes Regensburger continuously endeavored to increase the added value for domestic sheep’s wool in order to consolidate their “right to exist”, even in times when economic times were extremely difficult for the company. In order to come a step closer to this goal and to further improve the quality of the washed wool, the sheep wool washing plant commissioned in 1998 was rebuilt and extended in the summer of 2008. Older components of the machine were replaced by new ones, for example a new raw opener and a process-controlled belt weigher. Although the guidance of the handicraft enterprise is meanwhile in the hands of the two sons Michael & Joachim is still traded according to the same principles.